What If – an interactive story about IIoT and AI

An interesting interactive story featuring an operator dealing with an onboard machine alarm.

On February 29th, during the Machine Builder X event, we presented and demonstrated, through a live show, the process of replacing a welding bar using 40Factory Industrial IoT, GenAI, and VR technologies. In this article, we want to tell you the story that our audience experienced live. The main key players are:

Imagine yourself as a packaging line operator: while carrying out your daily routine tasks, you receive a notification from MAT indicating the occurrence of a specific alarm. That’s quite an issue!

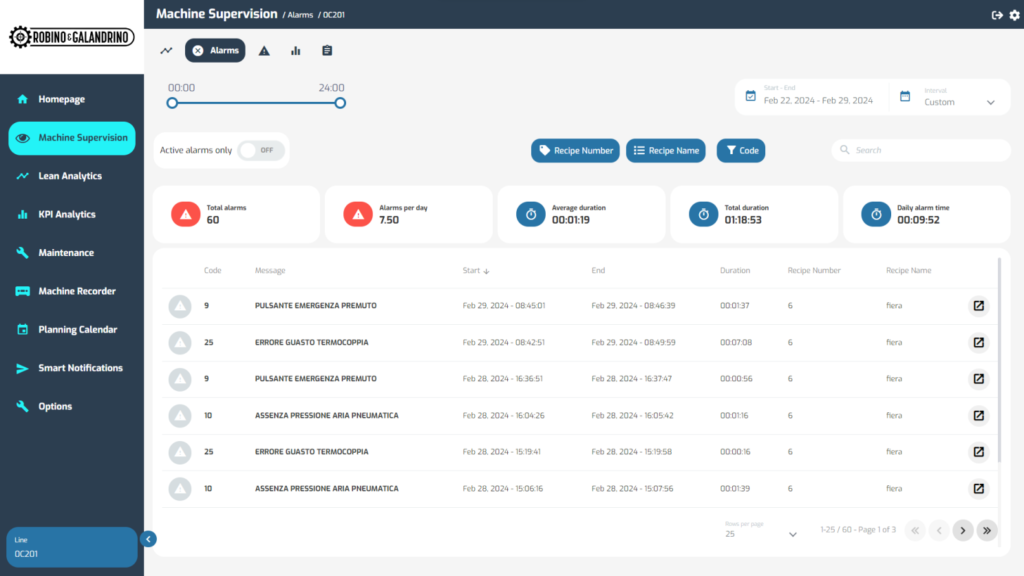

So you try to investigate: you log into MAT, open the “Machine Supervision” module, and indeed, you notice the presence of an alarm code that has been occurring repeatedly over the past few days. Intervening promptly is necessary!

At this point, what should we do?

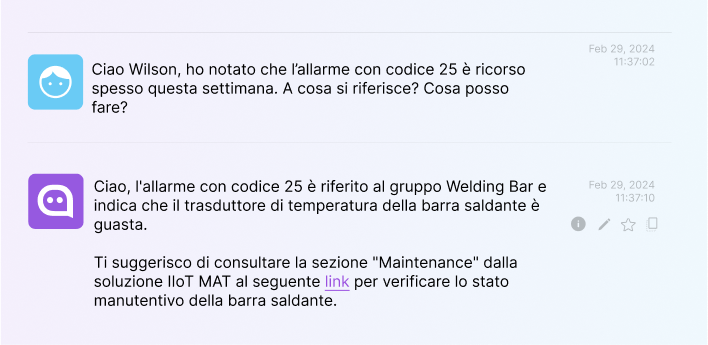

Fortunately, MAT integrates Wilson.ai, a virtual assistant that acquires and integrates MAT data with the entire technical documentation of the machines. With a certain concern, you turn to Wilson.ai to ask for more information.

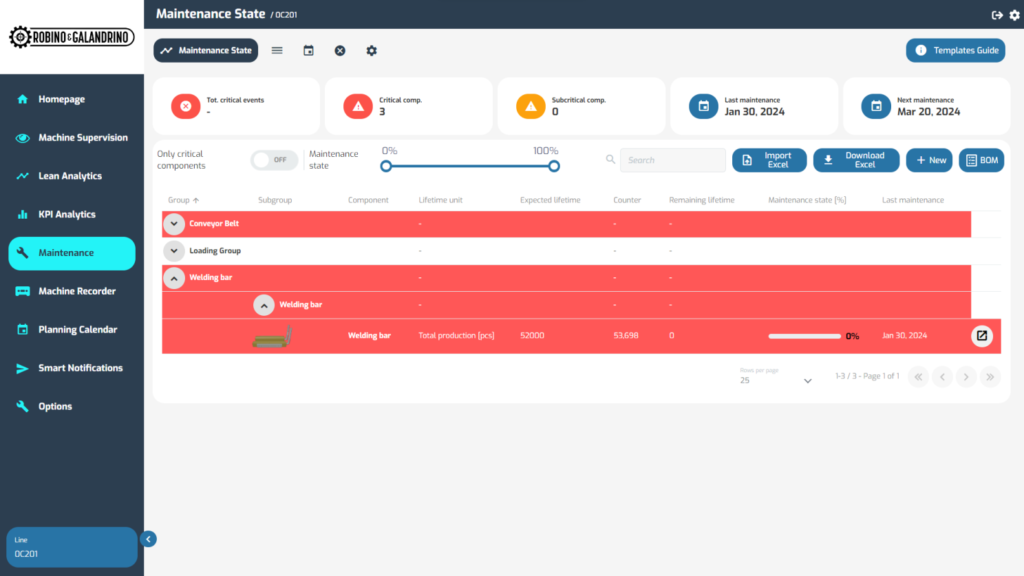

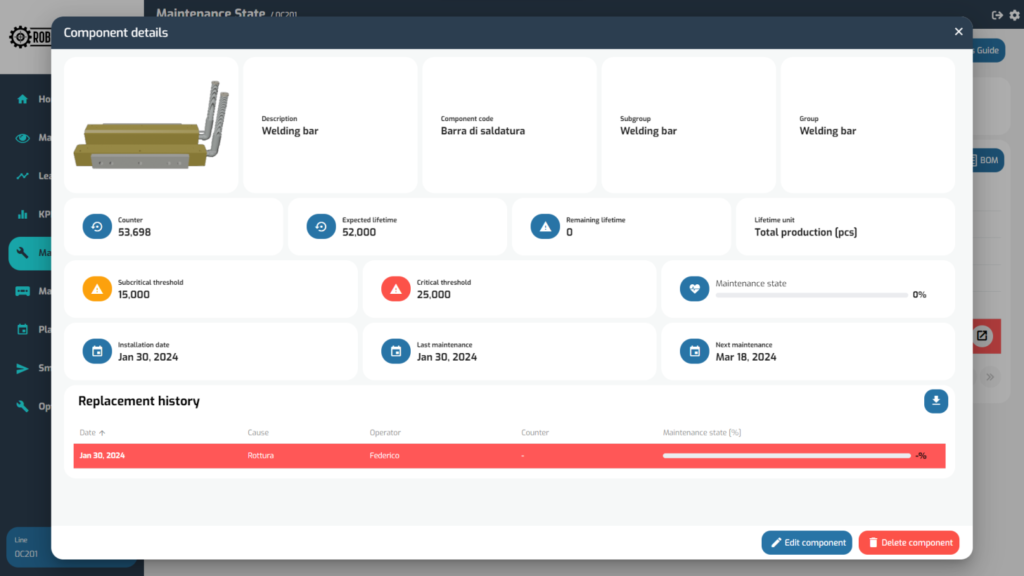

Wilson.ai suggests that there might be an issue with the availability of the welding bar. You click on the link provided and open the “Maintenance” module of MAT to check the maintenance status.

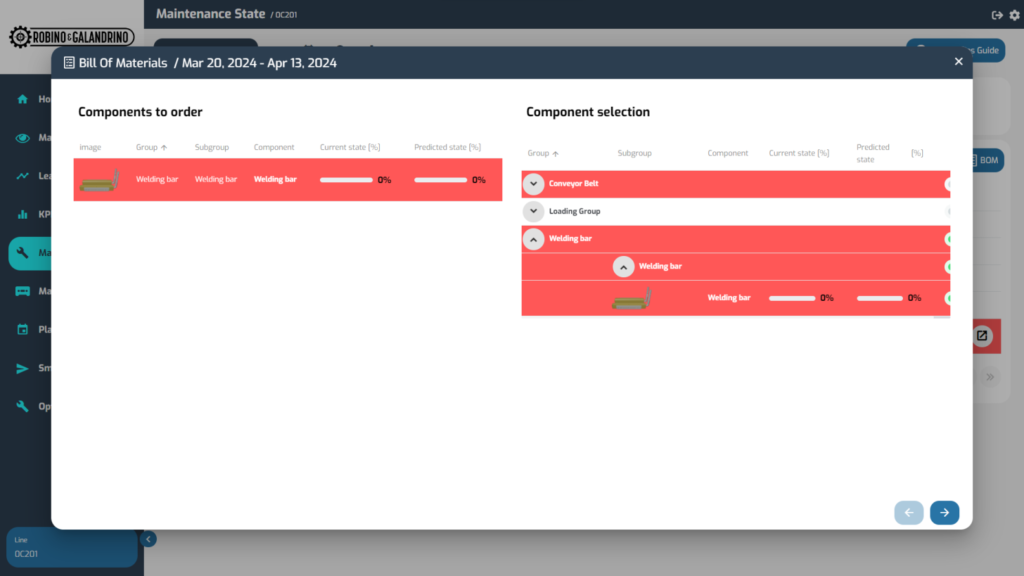

Indeed, the welding bar must be urgently replaced, or you risk losing many hours of productivity! Having reached this point, all that’s left is for you to click on “BOM” to automatically generate the bill of materials for ordering spare parts.

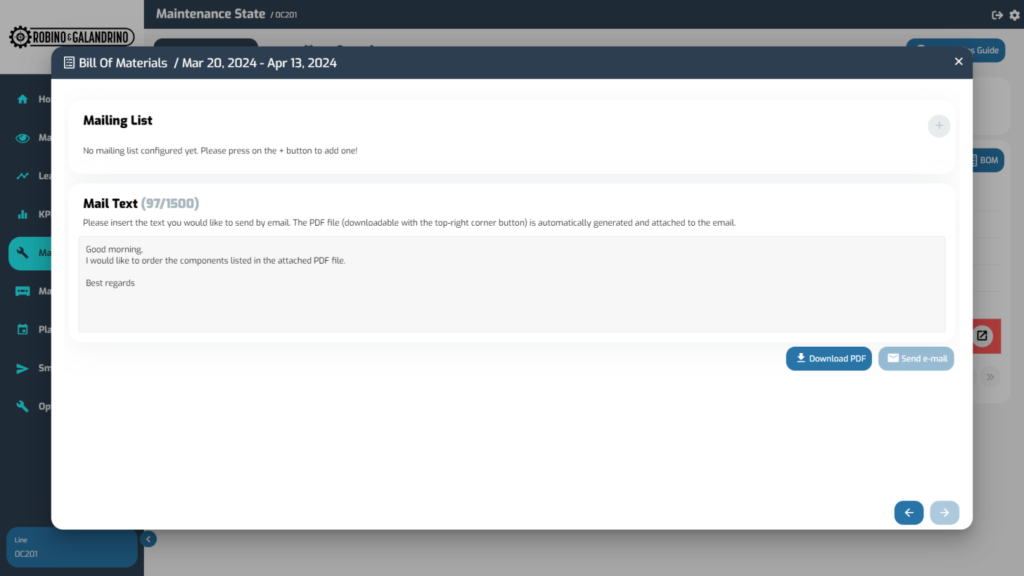

Once the BOM has been automatically generated, you proceed to submit the request to your supplier.

Subsequently, after sending the order and promptly receiving the replacement parts, it’s time to get hands-on with the machine. But here’s the dilemma: how to do it?

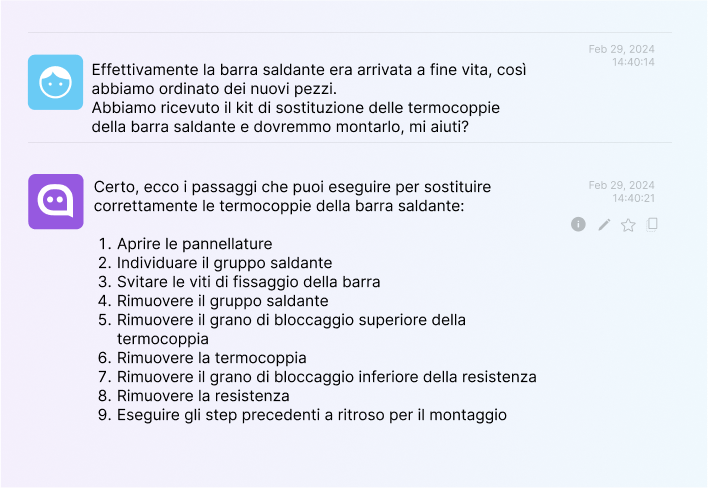

Your colleague, who is quite experienced in maintenance, has decided to take a nice week off. So, you’re left once again to rely on the expert mind of Wilson.ai.

You can breathe a sigh of relief: Wilson.ai has provided you with a series of steps to follow for a correct and safe procedure for replacing the thermocouples of the welding bar.

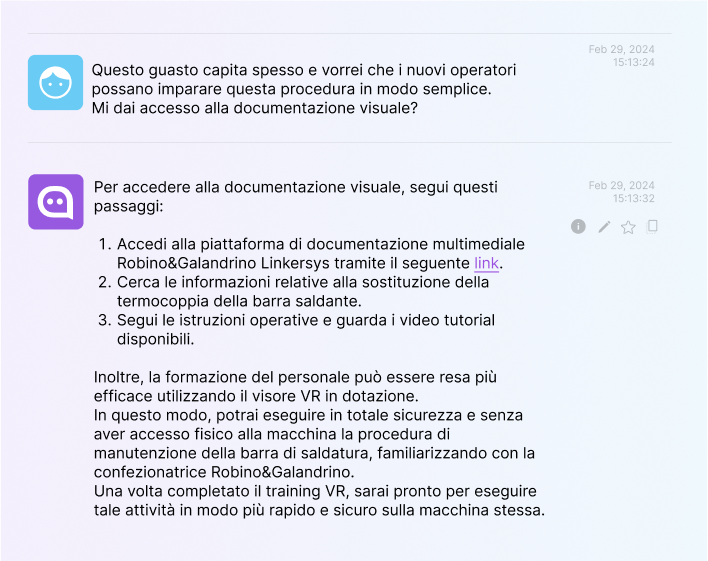

You proceed with the replacement, and meanwhile, you think that just these days a new resource has entered your department. Surely, it’s useful for them to learn how to perform this maintenance, so you turn again to Wilson.ai to request access to the 3D visual documentation.

Thanks to Linkersys, the platform by Desys integrated directly into MAT, you can access the 3D Visual Documentation. You open the link provided by Wilson.ai, enter the platform, and show it satisfactorily to your new subordinate.

You can click “play” to start the 3D video illustrating the procedure, and additionally, scroll through the webpage to review the related steps, accompanied by representative images of the actions to be taken.

But that’s not all: Wilson.ai, as a true prodigious assistant, has mentioned the possibility of using Virtual Reality for the training of your line staff. By wearing the provided VR headset, we can practice the maintenance procedure in complete safety, thus preparing ourselves best for the intervention on the actual machine.

In conclusion, an extraordinary experience that combines technology and operational convenience to ensure effective management of industrial maintenance!