FIMI IOT

FIMI's MAT

The Industrial IoT solution for managing complete plants and machines for metal coil processing.

Client

Presezzi Extrusion

Type

OEM

Sector

Extrusion

Presezzi Extrusion is an Italian company specializing in the design and manufacture of presses and plants for the extrusion of non-ferrous metals such as aluminum, copper, and brass. The company is recognized for its technological innovation, strong focus on sustainability, and ability to develop customized solutions. Headquartered in Vimercate (MB), with additional operational units in Lombardy, Presezzi Extrusion focuses on efficiency, flexibility, and quality, positioning itself as a reliable partner for the global extrusion industry.

The collaboration between Presezzi Extrusion and 40Factory began in 2023, following an internal strategic reflection on the role of digital technologies in the evolution of machines and the services offered to customers.

In the initial phase, Presezzi evaluated the possibility of developing proprietary software in-house to cover some of the functionalities now provided by PEAK. However, the analysis showed that competing in terms of development speed, scalability, and innovation capability would have required a level of resources and expertise that was difficult to sustain over time. This led to the decision to rely on 40Factory, recognizing its consolidated know-how in the Industrial IoT field and its ability to transform large volumes of industrial data into immediately usable and valuable information.

Presezzi’s goal was twofold:

The collaboration with 40Factory therefore fits into a broader digitalization journey, aimed not only at improving machine performance, but also at strengthening service value and the relationship between Presezzi and its customers over time.

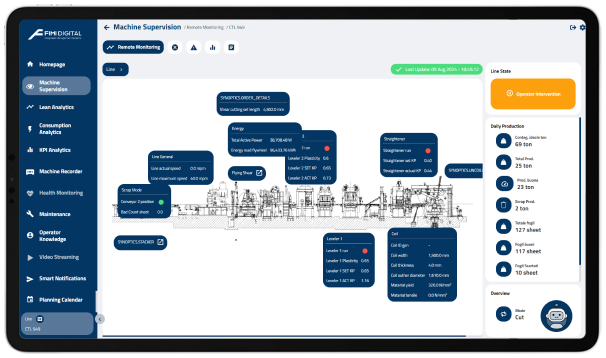

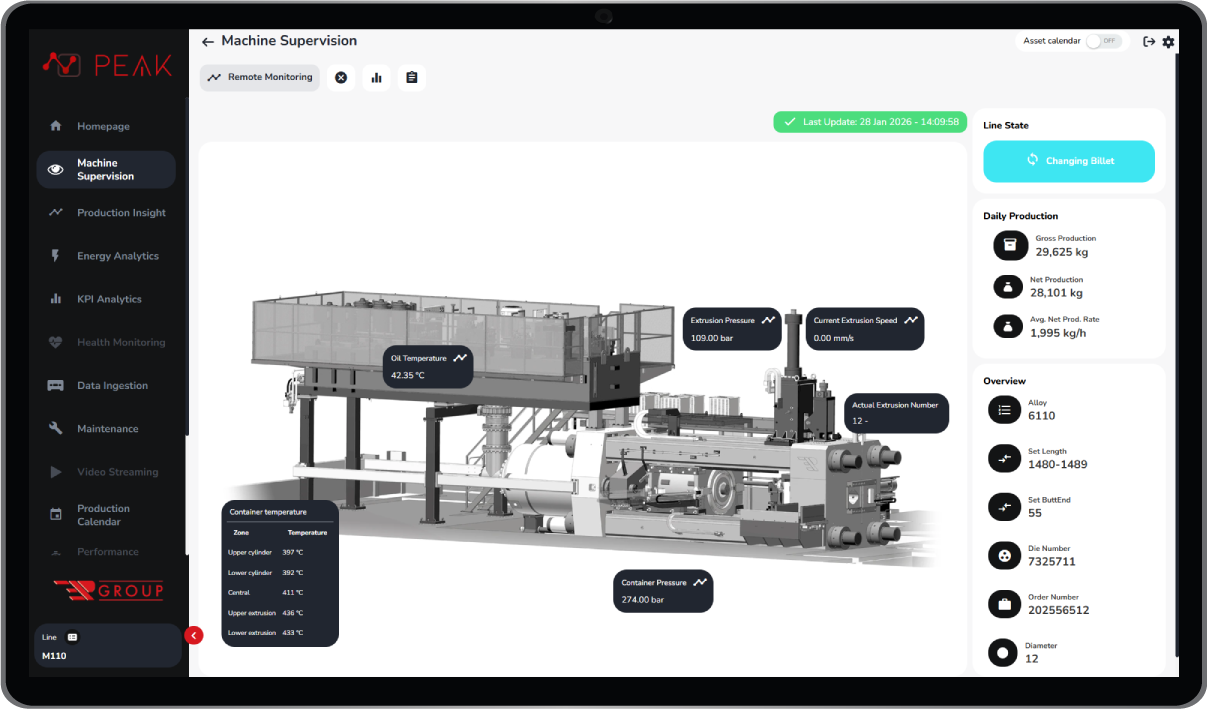

The answer to these needs came with PEAK (Presezzi Extrusion Analytics Knowledge), the IIoT platform developed to remotely monitor, manage, and optimize extrusion lines and foundry processes.

The platform is structured into dedicated modules, each designed to address a specific aspect of the production process, such as:

Thanks to PEAK, customers can access contextualized and structured information, ready to support both operational and strategic decisions, optimizing production processes, improving efficiency, and reducing waste.

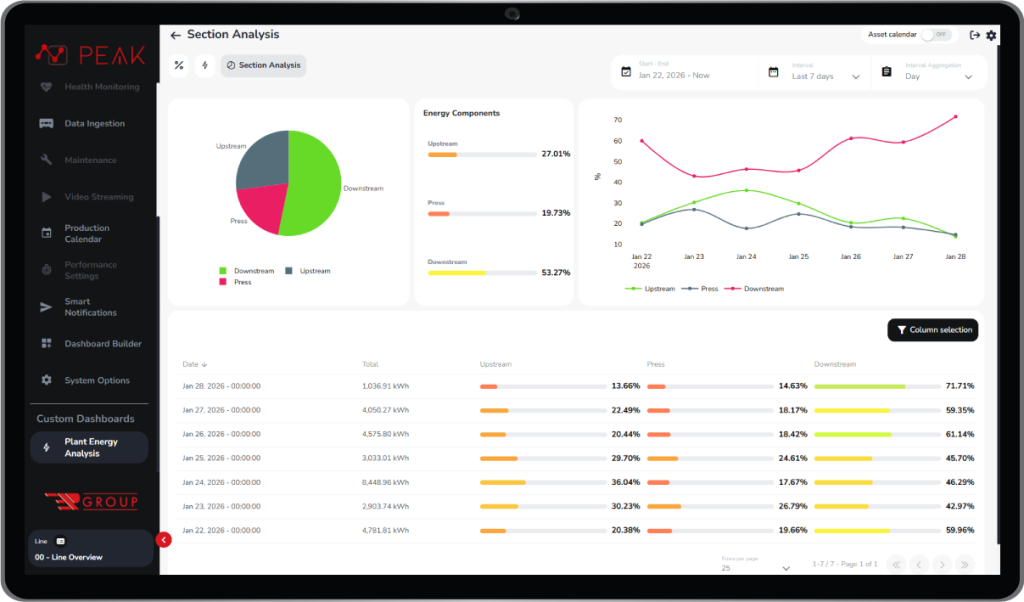

Among the most versatile modules within PEAK is the Dashboard Builder, a tool that allows customers to independently create customized pages within the platform, with charts and insights tailored to their specific operational and decision-making needs.

Using the Dashboard Builder, Presezzi developed an advanced dashboard focused on energy parameters for one of its customers. The dashboard was designed to demonstrate the actual energy consumption of the machine to government authorities, enabling access to public funding. This is a concrete example of how a dashboard can go beyond technical monitoring and become a strategic tool that supports economic and institutional decisions.

With industrial AI Agents, Presezzi completed its digital journey.

The most recent evolution of this digitalization path is represented by the introduction of industrial AI Agents. These agents leverage the operational data processed in PEAK and the technical documentation managed by the virtual assistant Wilson.ai, enabling Presezzi to carry out effective reverse engineering activities. This is a key step not only to further optimize machines, but also to provide end customers with advanced tools that improve production performance and reduce energy consumption.

The first industrial AI Agent developed is called EVA 01. EVA acts as an active digital sentinel: it monitors specific process parameters and, thanks to the knowledge directly transferred by Presezzi technicians, is able toidentify potential issues in advance during the billet heating phase for extrusion.

When a deviation is detected, EVA suggests corrective actions on furnace parameters, helping to prevent product scrap and ensure the quality of the final output. The agent also performs a retrospective analysis of furnace exit temperatures, categorizing them by alloy and billet length, and flags all conditions that fall outside predefined tolerances, proposing targeted corrective actions.

PEAK and the EVA 01 AI Agent represent an evolution in the way Presezzi observes and governs its machines. Data is no longer limited to monitoring, but becomes an operational tool to improve performance, prevent issues, and continuously refine plant behavior. An approach that strengthens the long-term value of the machine and enables new ways of supporting customers.